Wear-resistant Steel Plate

Classification :

PRODUCT DETAILS

Product Description

Chrome Carbide Overlay Wear Plate are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.

The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3-25mm

Wear plate size: 1500*3000, 1400*3000,1400*3400, 1400*3500, 2100*3500, customized.

Chrome Carbide Overlay Wear Steel Plate are used to make many complex wear parts to be positioned in high wear places.

We can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings.

1.Wear-resisting steel plate is composed of low Carbon Steel Plate and alloy wear-resisting layer. When working, the matrix provides comprehensive properties such as strength, toughness and plasticity of resisting external forces, and the alloy wear-resistant layer provides wear-resistant properties that meet the requirements of specified working conditions.

2.Wear-resisting steel alloy wear-resisting layer and base plate are metallurgical combination. By means of special equipment and automatic welding process, the high-hardness self-protecting alloy wire is uniformly welded on the substrate, and the composite layers are one to two or even more. In the composite process, due to the different shrinkage ratio of the alloy, uniform transverse cracks appear, which is a significant feature of the wear-resistant steel plate.

3.The wear resistant layer of the alloy is mainly chromium alloy, while manganese, molybdenum, niobium, nickel and other alloys are added. The microhardness of carbide can reach above hv1700-2000, and the surface hardness can reach hrc58-62. Carbide alloy has a strong stability at high temperature, maintain a high hardness, but also has a good oxidation resistance, within 500℃ completely normal use.

4.The wear-resistant layer has narrow channel (2.5-3.5mm), wide channel (8-12mm), curve (S, W), etc. It is mainly composed of chromium alloy, while manganese, molybdenum, niobium, nickel, boron and other alloy components are added. With 40-60% carbide content, the microhardness can reach above HV1700 and the surface hardness can reach hrc58-62.

Product Specification

|

Product |

Wear Resistant Steel Plate |

|

Standard |

AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

|

Thickness |

3-120mm |

|

Width |

600-1500mm, 1800-2000mm,2500-3500mm |

|

Length |

2000-3000mm, 6000-12000mm |

|

Grade |

NM360, NM400, NM450, NM500, AR360, AR400, AR450, AR500, AR550 QUARD400, QUARD450, QUARD500, FORA400, FORA500, RAEX400, RAEX450, RAEX500 |

|

Surface treatment |

Clean, blasting and painting according to customer requirement |

|

Technique |

Cold rolled and hot rolled |

|

Capacity |

10000 tons/month |

|

Package |

Export standard packing: wooden cases or boxes to be packed;We will pack the goods according to the factory's requirements for export. Or according to customer requirements.In addition,we will give the product good surface protection. |

|

Application |

metallurgy, coal, cement, power stntion, mining, building materials, petrochemical industry |

| Minimum Order Quantity | 25Tons |

NM360 NM400 NM450 NM500 Wear Resistance Steel Plate

Chemical Component

|

Steel/Grade |

C |

Si |

Mn |

P |

S |

AL |

Cr+Ni+Mo |

Nb+V+Ti |

|

NM360/AR360 |

0.10-0.30 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<0.6 |

Trace Amount |

|

NM400/AR400 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<0.9 |

|

|

NM450/AR450 |

0.10-0.40 |

0.20-0.40 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<1.2 |

|

|

NM500/AR500 |

0.10-0.40 |

0.20-0.45 |

1.00-2.00 |

≤0.015 |

≤0.003 |

≥0.20 |

<1.5 |

|

|

NM550/AR550 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

<2.0 |

|

|

NM600/AR600 |

0.10-0.50 |

0.20-0.45 |

1.00-1.50 |

≤0.015 |

≤0.003 |

≥0.20 |

<2.5 |

Mechanical Properties

|

Material |

Tensile MPA |

Elongation% |

Impact energy -20℃ |

HBW |

|

NM300 |

≥1000 |

≥14 |

≥24 |

270-300 |

|

NM360 |

≥1100 |

≥12 |

≥24 |

330-390 |

|

NM400 |

≥1200 |

≥10 |

≥24 |

370-430 |

|

NM450 |

≥1250 |

≥7 |

≥24 |

420-480 |

|

NM500 |

≥1250 |

≥7 |

≥24 |

≥470 |

|

NM550 |

≥1250 |

≥7 |

≥24 |

≥530 |

|

NM600 |

≥1250 |

≥7 |

≥24 |

≥570 |

Mn13 High Manganese Carbon Steel Plate

Chemical composition (%)

|

Material |

C |

Si |

Mn |

P |

S |

|

Mn13 |

0.90-1.20 |

0.30-0.80 |

11.0-14.0 |

≤0.035 |

≤0.30 |

Mechanical properties

|

Tensile Strength |

Yield Point |

Elongation |

Impact Resistance |

Initial Hardness (HB) |

Hardness after Hardened (HB) |

180° old Bending Test |

|

≥900MPa |

≥295 |

≥40% |

ak≥90J |

200-250 |

≥300 |

Qualified |

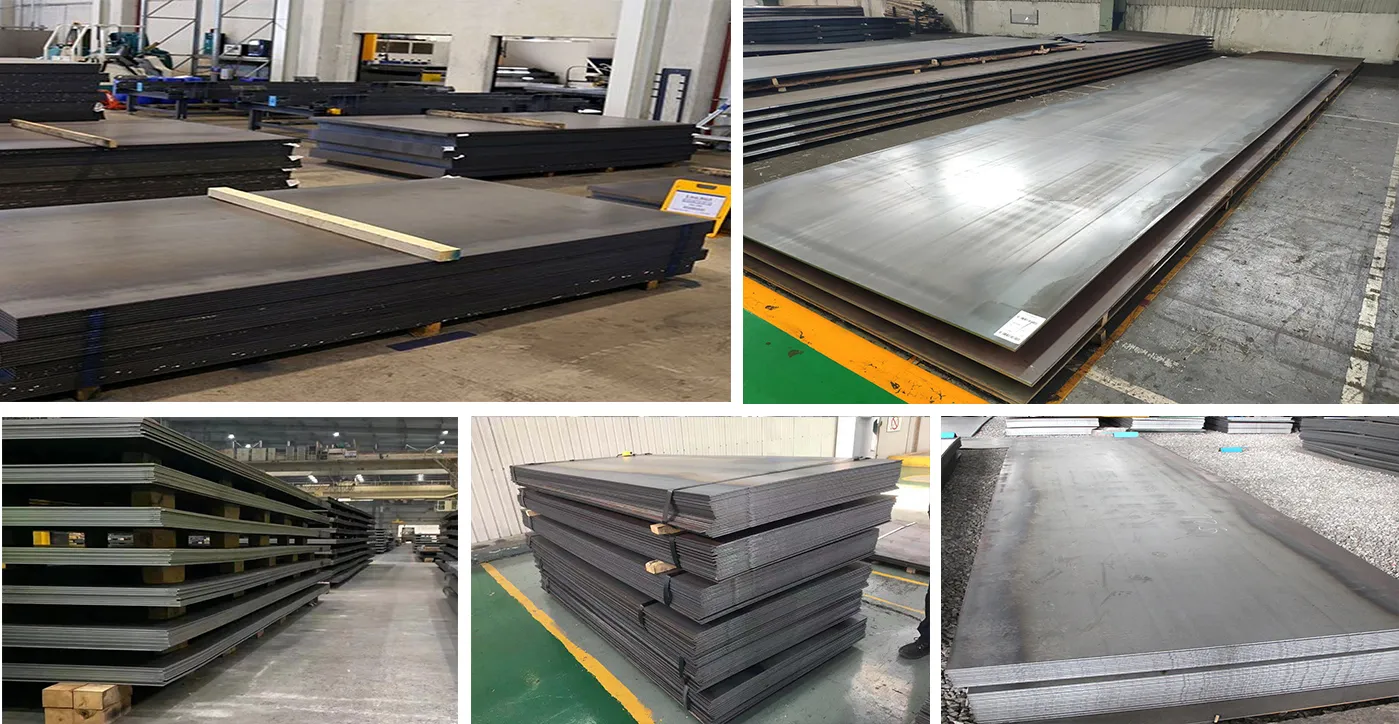

Factory Appearance

Wugang Steel (Qingdao) Co., Ltd. is located in Qingdao, China. It is a large enterprise specializing in the production and sales of steel products. The company produces and sells carbon steel plates/coils/tubes/rods, stainless steel plates/coils/tubes/rods, galvanized sheets/coils/tubes, color-coated coils, corrugated boards, rebar, wire rods and various types of materials. The company stocks The quantity is sufficient and the varieties and specifications are complete.

Packing and shipping

We are customer-centric and strive to provide customers with the best quality products and the best prices according to their cutting and rolling requirements. Provide customers with the best services in production, packaging, delivery and quality assurance, and provide customers with one-stop purchasing. Therefore, you can rely on our quality and service.

Customer visit

All staff of the company will uphold the spirit of "knowledge businessman" people-oriented, honest customers, excellent innovation, sustainable development, and is willing to work with you to develop together. Sincerely hope to cooperate with you!

FACTORY WORKSHOP

We are customer-centric and strive to provide customers with the best quality products and the best prices according to their cutting and rolling requirements. Provide customers with the best services in production, packaging, delivery and quality assurance, and provide customers with one-stop purchasing.

Customer Visit

Customer Visit

Production Workshop

Factory Workshop

Production Workshop

RELATED PRODUCTS

CERTIFICATE OF HONOR

OUR SERVICE

1 : Prime quality and reasonable price.

2 : Wide excellent experiences with after-sale service.

3 : Every process will be checked by responsible QC which insures every product's quality.

4 : Professional packing teams which keep every packing safely.

5 : Trial order can be done in one week.

6 : Samples can be provided as your requirements

FAQ

Q2:Does the product have quality inspection before loading?

A:Of course, all our products have undergone strict quality inspection before packing.

Q3:Can you provide the samples free?

Q4:What about product prices information?

A:Prices various according to periodic price changes of raw materials.

Q6:What is your terms of payment ?

GET A FREE QUOTE